Case Study: Solving Maintenance Headaches: How A Mineral Processing Company Cut Bolting Time by 83%

In mining and mineral processing, equipment reliability is essential to productivity. However, for a mineral processing company site in South Africa, a critical component—the coal separator bridge—presented a costly and time-consuming challenge. Through a strategic partnership with HYTORC, they transformed a 3-hour manual labor ordeal into a streamlined, 30-minute precision operation.

The customer required a solution to alleviate the need to manually torque the separator bridge bolts, HYTORC surveyed the application and provided a credible solution with the STEALTH tool and incorporated the washer system. An added feature was the use of the VECTOR Pump with downloadable data, this put the customer at ease, knowing the bolts were fastened to the specifications specified. - John Fairhurst, Corporate Account Manager: Africa

Challenge: Excessive Vibration & Loose Bolts

The plant’s superstructure was experiencing excessive vibration. This constant movement created a significant safety and maintenance issue causing the bridge bolts on the separator to consistently loosen.

To manage this, the maintenance team was forced to use "flogging" (manual striking of wrenches) as their primary method for tightening. There were several critical problems with this.

- Very Inconsistent Torque: Manual flogging could not provide the credible, repeatable torque values required to keep bolts secure under high vibration.

- Frequent Maintenance: The customer had to allot time for flogging as a regular part of the maintenance schedule because bolts were becoming loose.

- Labor Intensive: Tightening those bolts was a grueling process that took approximately 3 hours to complete.

- Unsafe: Manual flogging was more likely to result in worker injuries than using hydraulic torque tools.

HYTORC Solution: Controlled Torque & Precision Hardware

Our solution specialists saw how inconsistency in torque values caused the bolts to loosen over time. To solve this, HYTORC recommended a transition to a controlled torque system featuring these innovations:

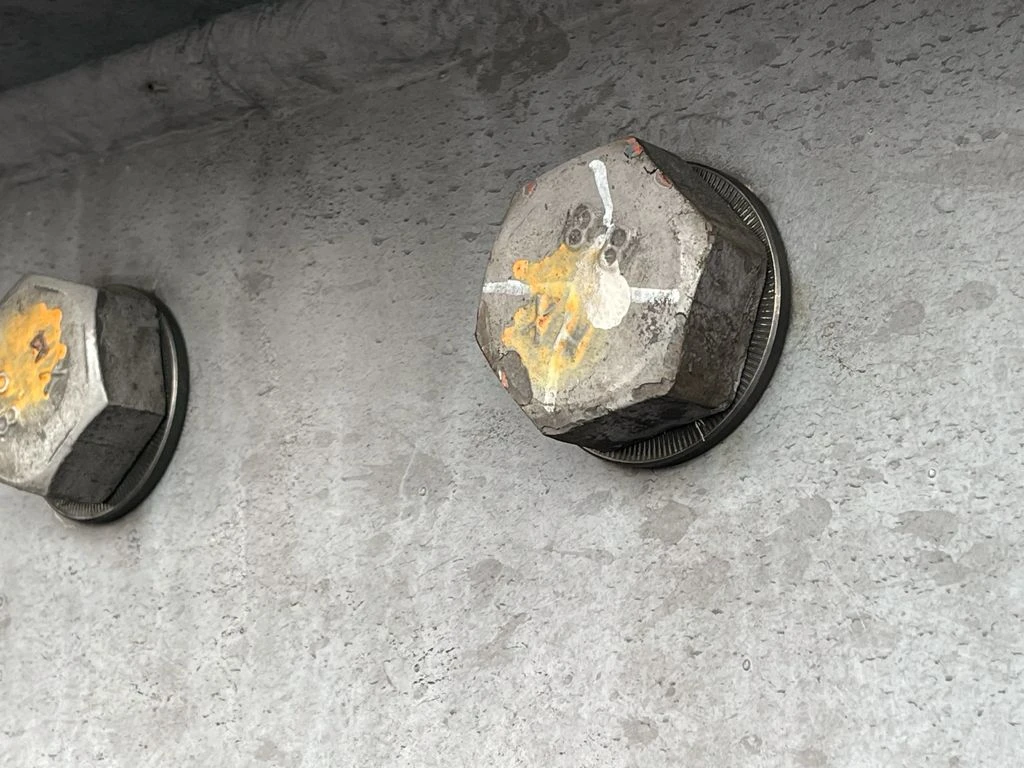

1. HYTORC Washer System: HYTORC Reaction Washers and Backup Washers eliminated crush points, keeping workers safer.

2. HYTORC STEALTH Tool & VECTOR Pump: To drive the new system, the team used low-profile hydraulic STEALTH tools that were powered by a VECTOR pump. This combination allowed the team to reach the required torque value with absolute precision and repeatability.

Results: Better Efficiency & Reliability

Switching from manual flogging to using HYTORC’s controlled torque system had immediate and measurable results for our customer.

- 83% Reduction in Labor Time: Total tightening time plummeted from 3 hours down to just 30 minutes.

- Repeatable Accuracy: all bolts now had documentable, credible, and repeatable torque values, ensuring the bridge remains secure despite excessive plant vibration.

- Improved Maintenance Strategy: By using a controlled torque system from HYTORC, our customer addressed the inconsistency problem that contributed to bolts loosening over time.

Fast Facts

- Bolt Size: M39

- Nut Size: 60mm A/F

- Torque Value: 2,700 Nm

- Bolting Time Saved: 2.5 hours per session

Moving Forward

By embracing advanced bolting technology and moving away from outdated, dangerous manual methods, the mining company secured its superstructure and freed up hours of maintenance time. This success paved the way for further HYTORC application solutions across their sites.

Get in touch to learn how HYTORC can help you achieve time savings.