Case Study: Revolutionizing Nuclear Facility Bolting - How the HYTORC Nut Cut Downtime by 60%

In the nuclear power industry, safety, reliability, and precision are non-negotiable. For years, traditional bolting methods at nuclear facilities presented constant challenges of being time-consuming. This contributed to costly downtime, and, most critically, posed inherent safety risks to highly skilled technicians due to dangerous pinch points.

What if one innovative solution could virtually eliminate these risks, drastically reduce maintenance time, and guarantee unmatched bolting precision? Leading nuclear power providers are finding the answer in the HYTORC Nut tensioning fastener.

The Core Challenges of Nuclear Facility Bolting

A major national nuclear power provider sought a safer and faster way to manage essential bolting tasks on critical components like large flanges and steam turbines. The main issues they needed to solve were:

- Worker Safety: Manual torque wrenches created dangerous pinch points, putting technicians at risk during operations.

- Time & Efficiency: Manual bolting on large components could take hours, leading to significant downtime and bottlenecking critical maintenance schedules.

- Precision & Integrity: It was a challenge to ensure exact, consistent bolt loads without introducing damaging sideloads or torsional forces, which compromised the long-term integrity of the joint.

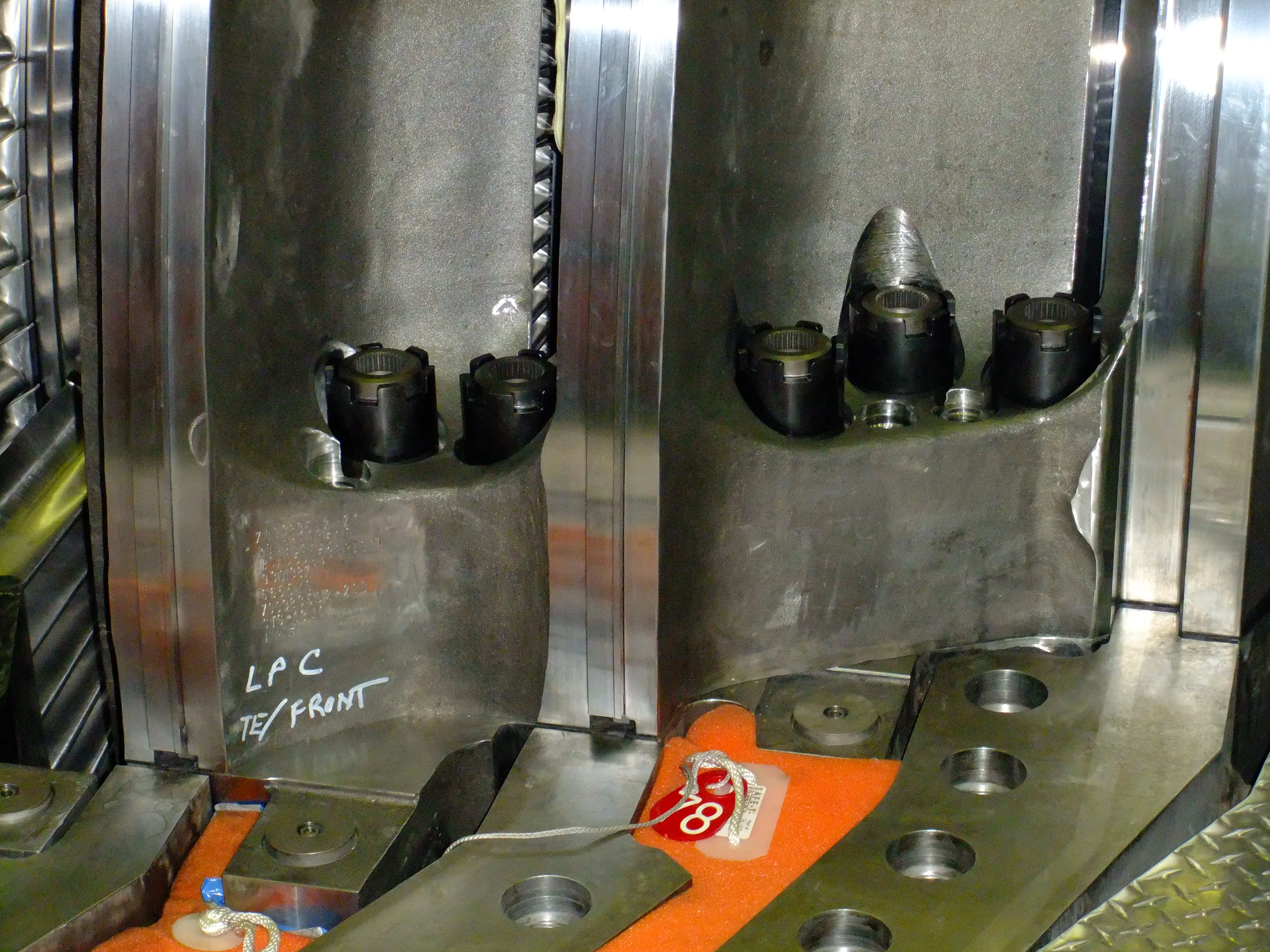

The Game-Changing Solution: The HYTORC Nut

The nuclear organization initiated rigorous, independent validation tests of the HYTORC Nut to find a solution that minimized risks, improved efficiency, and enhanced bolting precision across all their facilities.

The results were overwhelmingly positive. The HYTORC Nut proved to be a transformative solution for nuclear facility bolting, specifically by:

1. Massive Time Savings – Up to 60% Reduction!

When tested on a common flange with 20 studs:

- Conventional Methods took over an hour to complete.

- The HYTORC Nut System took approximately 20 minutes using just four tools simultaneously—a massive 60% time reduction! This translates directly to faster maintenance turnarounds and significantly reduced downtime.

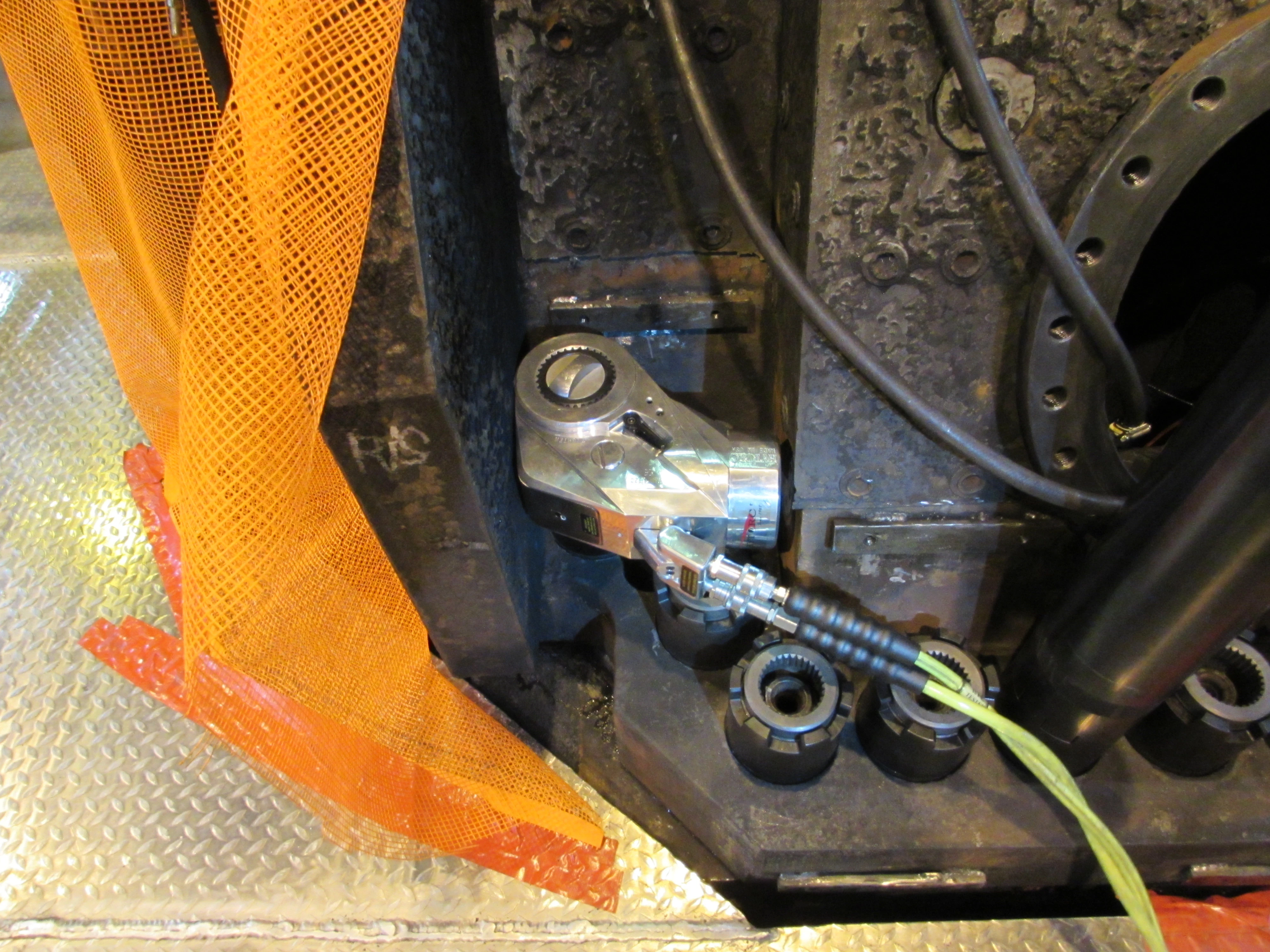

2. Pinch Point-Free & Enhanced Bolting Safety

The HYTORC Nut doesn’t need a reaction arm, thereby eliminating dangerous pinch points. Crews were able to perform bolting tasks with a drastically reduced injury risk, prioritizing the well-being of the workforce without compromising performance.

3. Pure Precision & Integrity

Unlike traditional torque methods that twist bolts, the HYTORC Nut consistently delivers pure axial tension. This ensures precise, calibrated bolt loads without introducing compromising side loads or torsional forces. The result is enhanced integrity and long-term reliability for critical nuclear components.

4. Simplified Operations

The innovative design of the HYTORC Nut removes the need for a backup wrench, simplifying the tool setup and mitigating the risk of thread damage (galling). It also allows for parallel closure (simultaneous bolting with multiple tools) in almost any position.

The Future of Nuclear Bolting Safety

The compelling study data led to a strong recommendation to approve the HYTORC Nut for application wherever warranted. This powerful evidence is now being presented for fleet-wide approval, setting a new industry standard for bolting safety, speed, and precision in nuclear facilities.

Ready to see how the HYTORC Nut can revolutionize maintenance at your facility and cut critical downtime? Get in touch and request a demonstration today!