Reinventing Bolting – One Washer at a Time

If you've ever worked with bolted joints, you know the routine: torque wrench in one hand, reaction arm in the other, trying to find a secure abutment point while avoiding pinch zones. But what if you could forget all that? The HYTORC Washer System means you can.

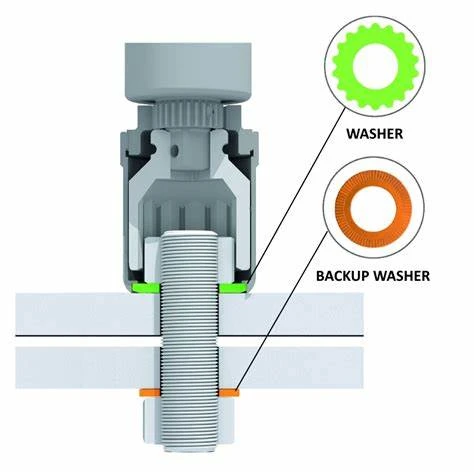

The genius of this system lies in its simplicity. Instead of relying on a dangerous, external reaction arm, HYTORC’s patented washer works with a dual layered socket. The outer socket grips the washer; the inner turns the nut. It’s a clean, contained action that nullifies side forces and internal stresses that plague traditional torque tools.

By keeping action and reaction on the same axis, the system delivers not just safety but precision. The bolt load is more consistent across the flange—something even the best torque tools can’t guarantee when paired with standard washers and reaction arms. This ensures better joint integrity and prevents problems like unintentional loosening or bolt yield.

Tool wear is also reduced. No more stress fractures from awkward counterforces or bent tool arms. Your torque equipment—like the award-winning Lithium Series II (LST) or the jGun Digital—lasts longer and performs better.

Best of all? You don’t need to replace your fasteners. Just switch the washer, and suddenly, you’ve upgraded to the most intuitive, operator-friendly system in the industry.

It’s time to rethink how we bolt. Say goodbye to reaction arms, and hello to a smarter, safer future with HYTORC.