Case Study: Flying High with HYTORC Netherlands

A leading European cargo airline faced significant challenges in maintaining the landing gears of their long-range wide-body airliners. The maintenance process required precise handling and efficient tools to ensure safety and reliability. HYTORC Netherlands provided innovative solutions that addressed these challenges, improving both efficiency and safety in the maintenance operations that addressed the specific challenges of working within narrow spaces and on sensitive materials.

Challenge:

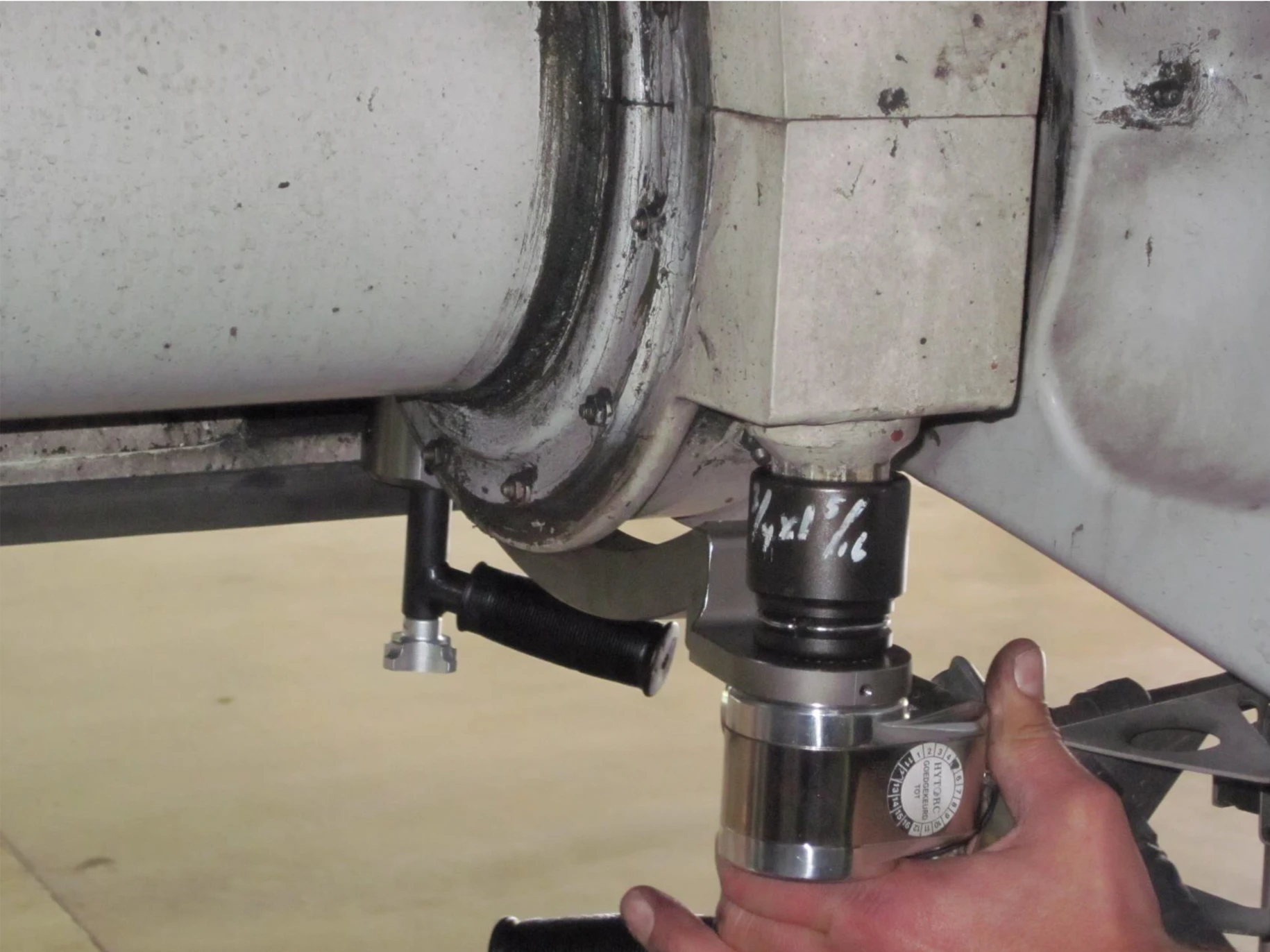

The primary challenges included the need for applying precise torque and the difficulty of working within the narrow confines of the aircraft's landing gear structure. Traditional tools were expensive, uncomfortable, and posed risks to both the equipment and technicians. Additionally, crews couldn’t use the aluminum aircraft construction as a reaction point, complicating the maintenance process.

HYTORC Solution:

- Cost Savings - The HYTORC tool and accessory solutions were significantly less expensive than the product the customer previously used.

- Efficient Maintenance: Using AVANTI torque tools with specialized reaction arms and 12-point sockets gave the customer a more comfortable and efficient solution for maintenance tasks.

- Precision: The customer was able to get precise torque application without risking damage to the aircraft's aluminum structure.

- HYTORC demonstrated commitment to providing innovative and reliable solutions for the aerospace industry.