Case Study: How HYTORC Helped A South African Oil & Gas Facility Slash Bolting Time by 60%

In the oil and gas industry, companies pursuing a more efficient operation must also take safety, stability, and precision into account. A recent case study from South Africa highlights how transitioning from traditional hydraulic methods to advanced pneumatic tensioning systems can improve steam line maintenance.

Key Application Specs:

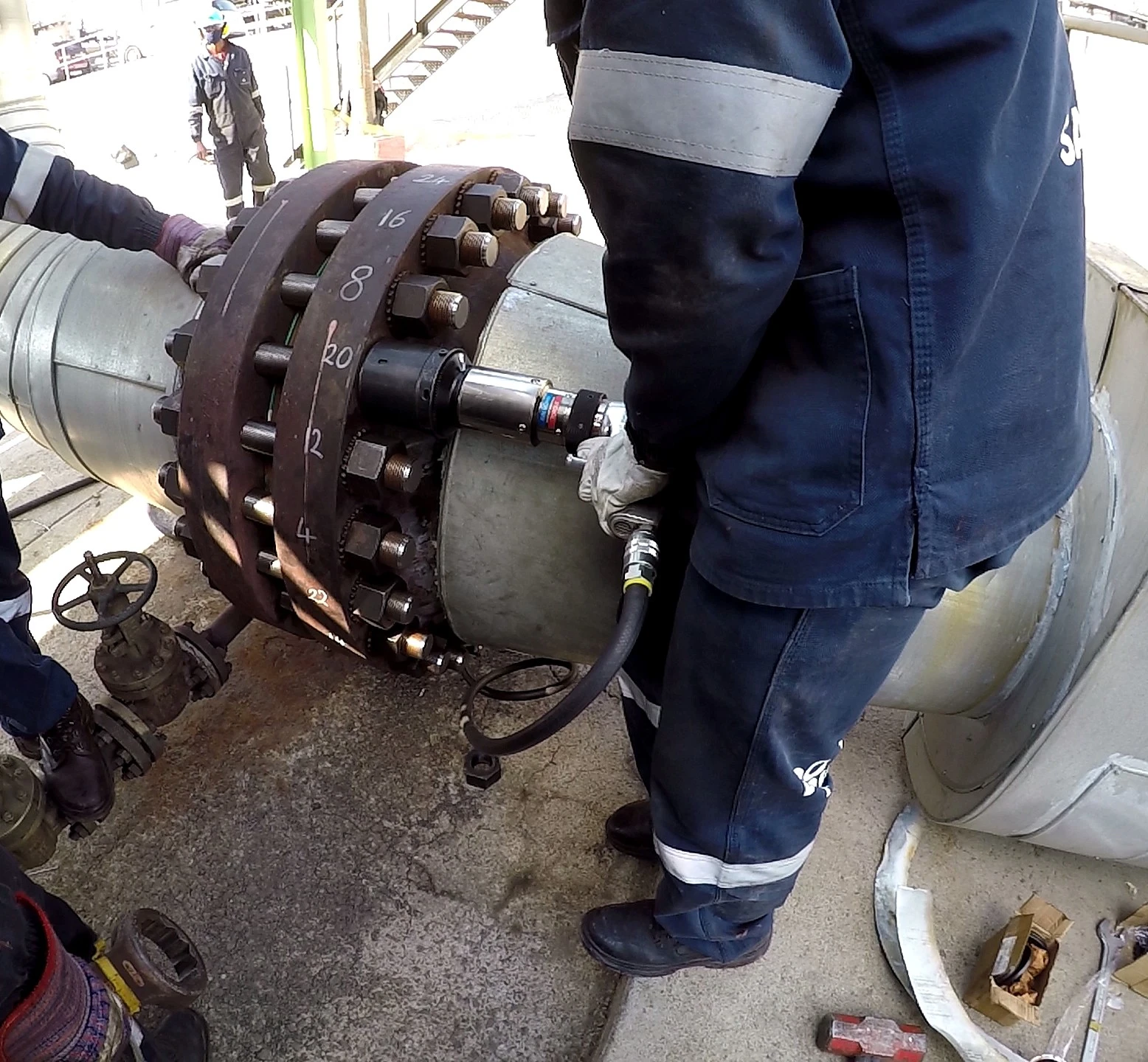

- Machine: 24" 600 Class Flange

- Bolt Size: M42 with a 4.5 mm thread pitch

- Nut Size: 65 mm A/F

- Operating Temperature: 482° F/250° C

The Challenge: Reducing Complexity on High-Temp Steam Lines

The customer, operating a 24" 600 Class Flange on a steam line, faced a common industry bottleneck thanks to complex bolting procedures that required specialized contractors. Operating at temperatures over 400°F/200°C with moderate vibration, the application required a solution that was robust enough for volatile environments but simple enough for in-house teams to manage.

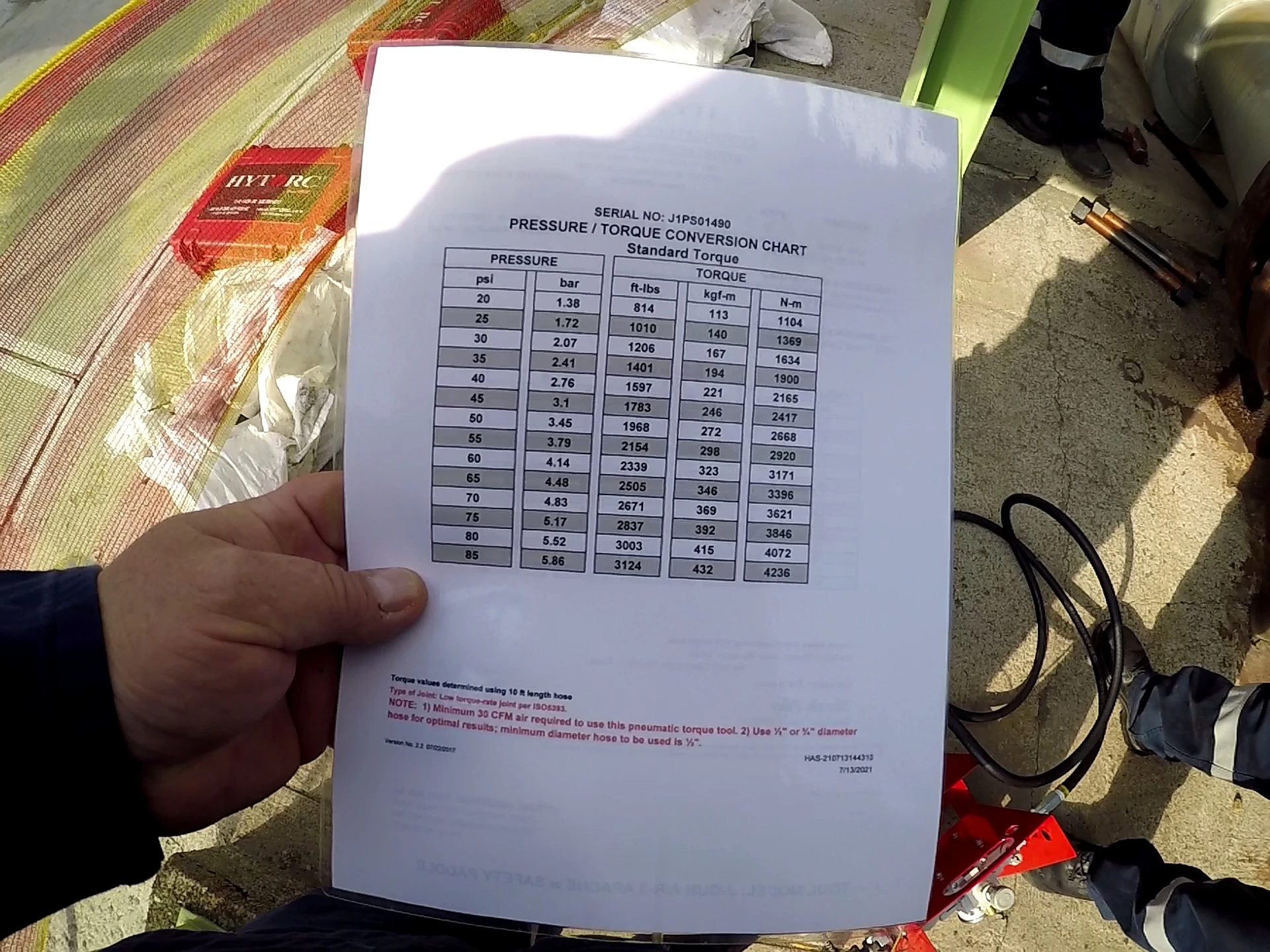

The customer requested a system that could provide safety and be reliable in sealing, without enduring additional maintenance costs. HYTORC recommended the jGUN DUAL SPEED tool due to the ATEX factor, coupled with the HYTORC Washer, this alleviated all the concerns with added compliance to industry standards. --John Fairhurst, Corporate Account Manager: Africa

HYTORC Solution: The HYTORC Washer & jGUN DUAL SPEED

After surveying the site, HYTORC proposed a shift away from standard hydraulic tools. The recommendation focused on two primary components:

- HYTORC Reaction Washer: This specialized fastener eliminated the need for external reaction arms, making bolting safer and simpler.

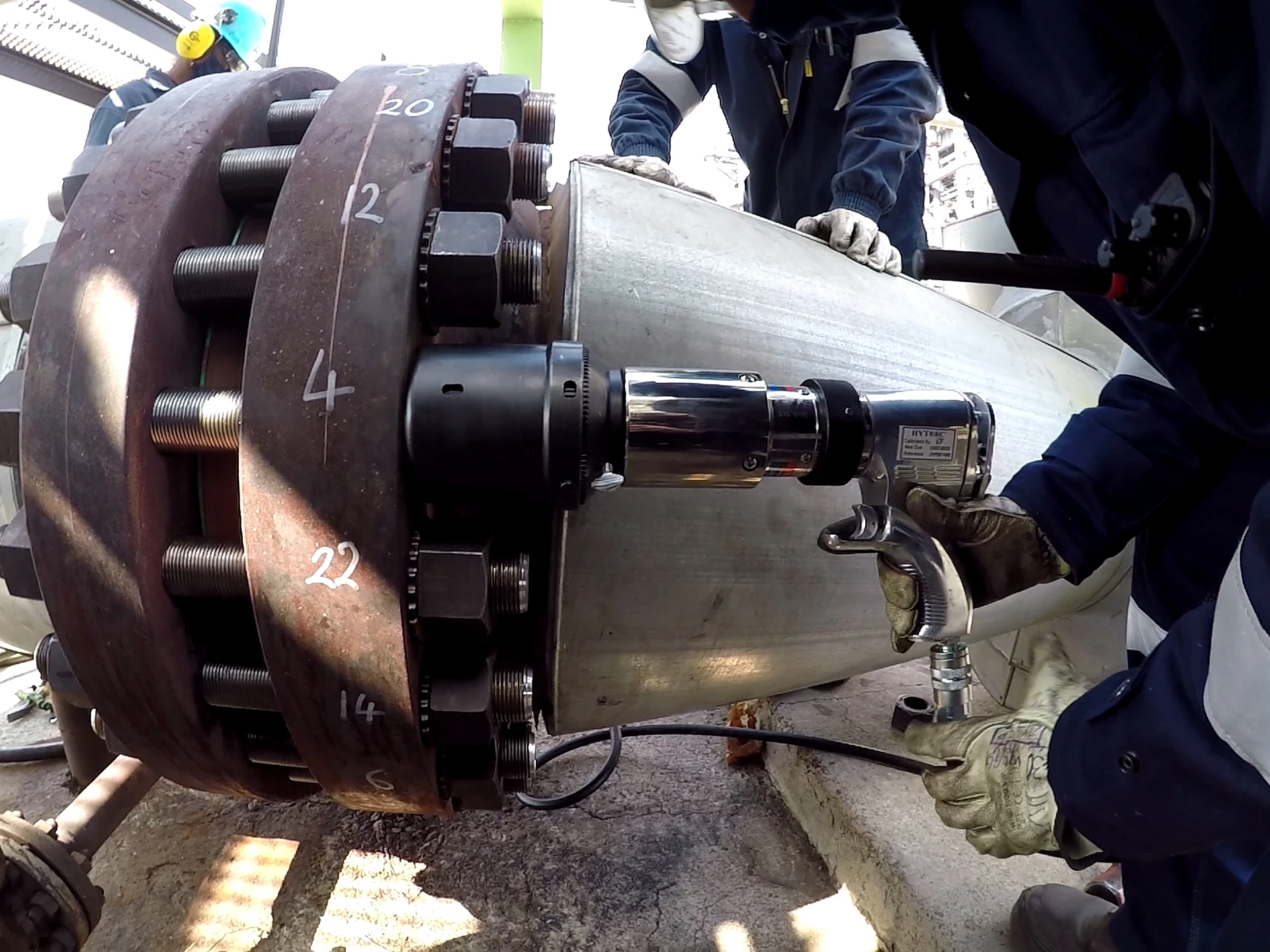

- jGUN DUAL SPEED: This pneumatic torque tool was chosen specifically for its ability to be used in volatile areas.

How They Did It

The team implemented a singular tool bolting pattern using a torque value of 3,600 Nm. To ensure maximum joint integrity, the bolting was performed in stages:

- Initial Pass: 30% torque

- Second Pass: 60% torque

- Third Pass: 100% torque

- Final: A comprehensive check pass

Results: Empowering the In-House Team

The results were immediate and measurable. By switching to the HYTORC system, the facility achieved:

- 60% Reduction in Bolting Time: The simplicity of the setup was faster than previous methods.

- In-House Capability: The customer successfully moved bolting in-house, removing their reliance on outside contractors.

- Improved Safety: The jGUN DUAL SPEED and HYTORC Washer system simplified setup complexity and provided a safer alternative to what they had been doing previously.

Future-Proofing Operations

Following the success of this 24" flange application, the customer decided to purchase various sizes of the HYTORC Washer for their entire range of flanges. This transition ensures that future maintenance cycles are safer, and more efficient.

Optimize Your Bolting Workflow

Are you looking to reduce downtime and take control of your facility's maintenance? HYTORC’s Productivity Enhancement Group (PEG) specializes in custom solutions for the most demanding industries.

Contact us to see how HYTORC can help you.