HYTORC Provides Bolting Solutions for a Petroleum Refinery Turnaround

Background

In September 2022, a petroleum refinery in the state of Washington faced a critical challenge when it had to prepare for an 8-week turnaround event requiring 24/7 support. The refinery’s need for updated torque and tension equipment was imminent to ensure the efficiency and safety of its operations. To address this issue, the company initiated a competitive bid process to identify a suitable partner for the project. The request for proposal was complex, with stringent requirements to ensure the success of the turnaround.

Customer Challenge

Outdated Tool Inventory

The refinery's inventory was primarily equipped with aging industrial tooling. These tools had become unreliable and were no longer capable of meeting the refinery's operational requirements. It was clear that a comprehensive update was needed to ensure the success of the upcoming turnaround.

Past Experience

In the past, the refinery faced challenging bolting needs during turnarounds. They knew that if 24/7 on-site support was not provided, operational challenges leading to costly delays were more than probable. This prompted the refinery to seek a dependable partner for its bolting requirements.

Chris Paraghamian of HYTORC Northwest took decisive actions to ensure unwavering support during the demanding 8-week turnaround.

How HYTORC Went Above and Beyond to Provide Support

HYTORC was chosen for the job based on its reputation for delivering reliable, high-quality bolting systems and its ability to provide exceptional on-site support.

On-Site Assistance

Chris Paraghamian of HYTORC Northwest took decisive actions to ensure unwavering support during the demanding 8-week turnaround. They strategically secured an Airbnb just 5 miles from the refinery and provided a HYTORC Service Van Technician on-site, standing ready to give emergency assistance to contractors throughout the entire outage period.

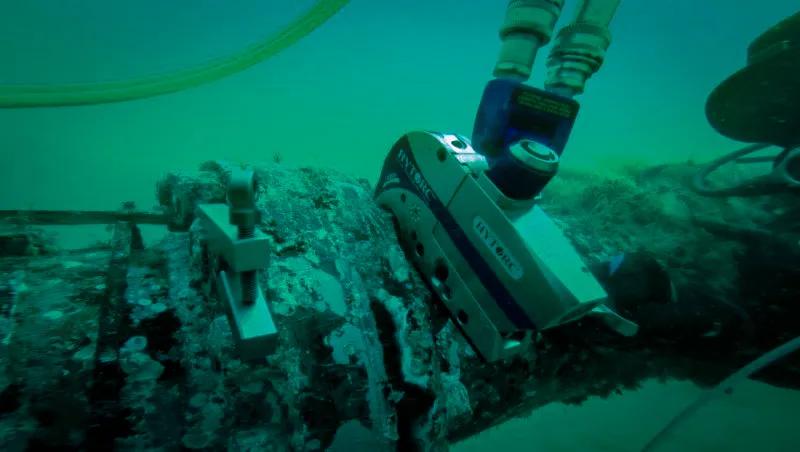

Mobile Equipment Trailer

A dedicated company trailer was stationed at the refinery to ensure they had all the necessary tools and equipment on-site. This trailer was equipped with a comprehensive inventory of essential tools, including hydraulic and FRL pumps, links, clicker wrenches, tensioners, and hoses.

Chris Paraghamian of HYTORC Northwest went the extra mile by offering three safety training classes to contractors and their teams.

Equipment Rental

In addition to the original rental agreement, the award-winning Lithium Series II electric torque tool was provided for rental, further enhancing the flexibility and options available to the refinery and its contractors.

Safety Training

Chris Paraghamian of HYTORC Northwest went the extra mile by offering three safety training classes to contractors and their teams. This commitment to safety and training contributed to a more efficient and secure working environment.

24/7 Support

The continuous on-site support provided by HYTORC Northwest and Mobile Services over the 8-week turnaround period demonstrated their reliability and commitment. This proved to be a crucial factor in the refinery's success, and they recognized HYTORC as the right choice for their bolting needs.

Rental Credits

Throughout the turnaround, the refinery accumulated a substantial number of rental credits, which were later applied toward the purchase of Lithium Series II electric tools, along with MXT+ and Stealth hydraulic torque wrenches. The transaction was completed in September 2023, further solidifying HYTORC as a trusted partner for industrial tooling.

The Result

Positive Contractor Feedback

Contractors working on the project reported extremely positive experiences while collaborating with HYTORC. This feedback played a pivotal role in the refinery's decision to hire HYTORC again for their Spring 2024 turnaround, establishing a long-term partnership.

Future Collaboration

The refinery is planning to update its aging tooling inventory with HYTORC Bolting Systems, highlighting the confidence and trust they have developed in this partnership.

In summary, HYTORC's steadfast dedication to delivering extensive support, coupled with their high-quality bolting equipment and dedication to safety, positioned them as the optimal choice for the crucial turnaround at this petroleum refinery. The collaboration established during this project has set the stage for ongoing cooperation and the revision of their bolting systems within the refinery's operations.