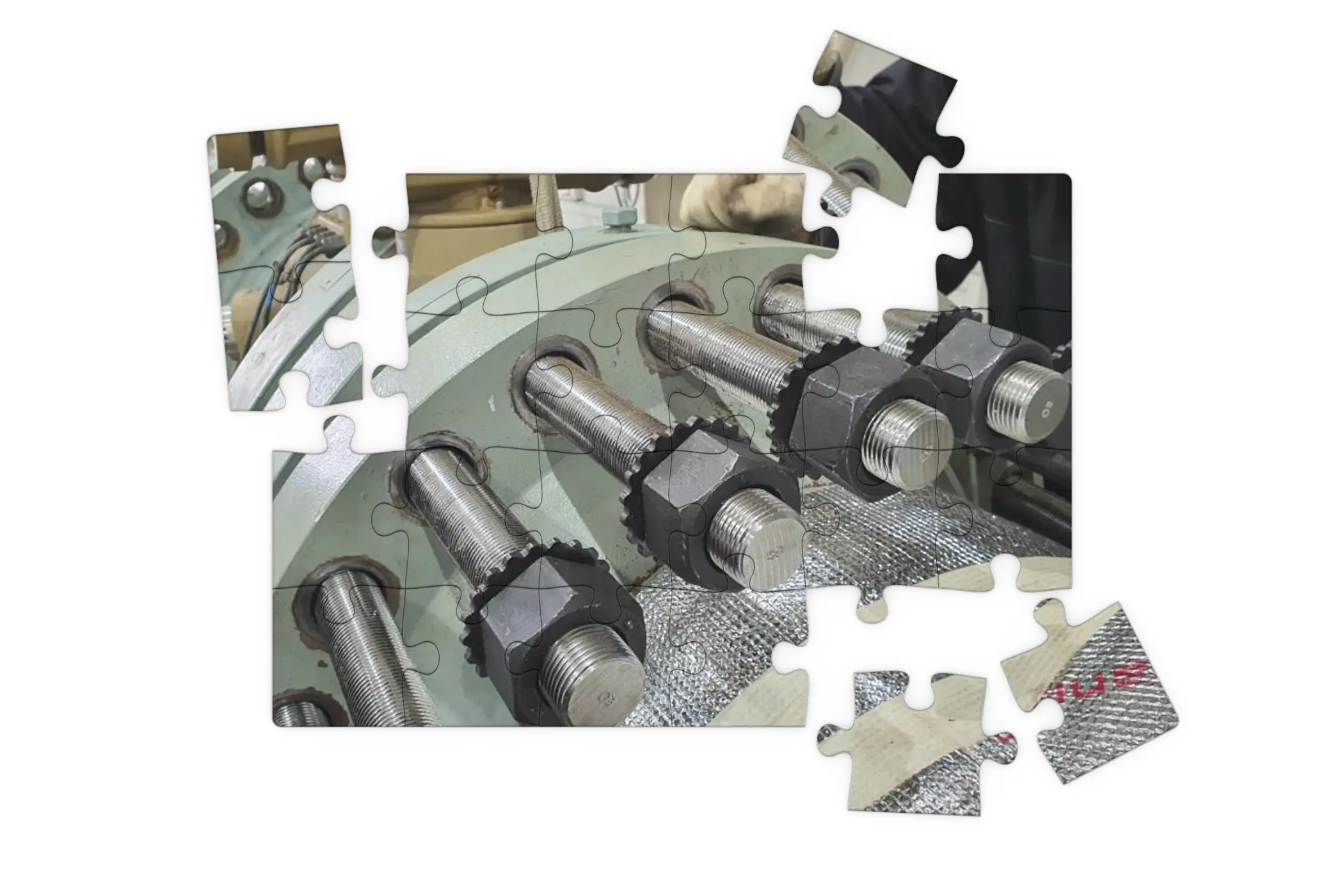

The HYTORC Washer - A Key Piece of the Puzzle

Sometimes, the best innovations are the most intuitive. The HYTORC Washer System is exactly that—a solution so straightforward that many wonder why it hasn’t always been the standard.

Standard bolting setups are a logistical puzzle. Finding reaction points, fitting fixtures in tight spaces, coordinating backup spanners—each step adds complexity, danger, and delay. For offshore and remote applications, it’s even worse. If a reaction fixture doesn’t fit, you could wait weeks for a replacement. For plant equipment, machinery may have to be designed to add in a reaction point that adds thousands of unnecessary dollars the manufacturing process of each piece of equipment.

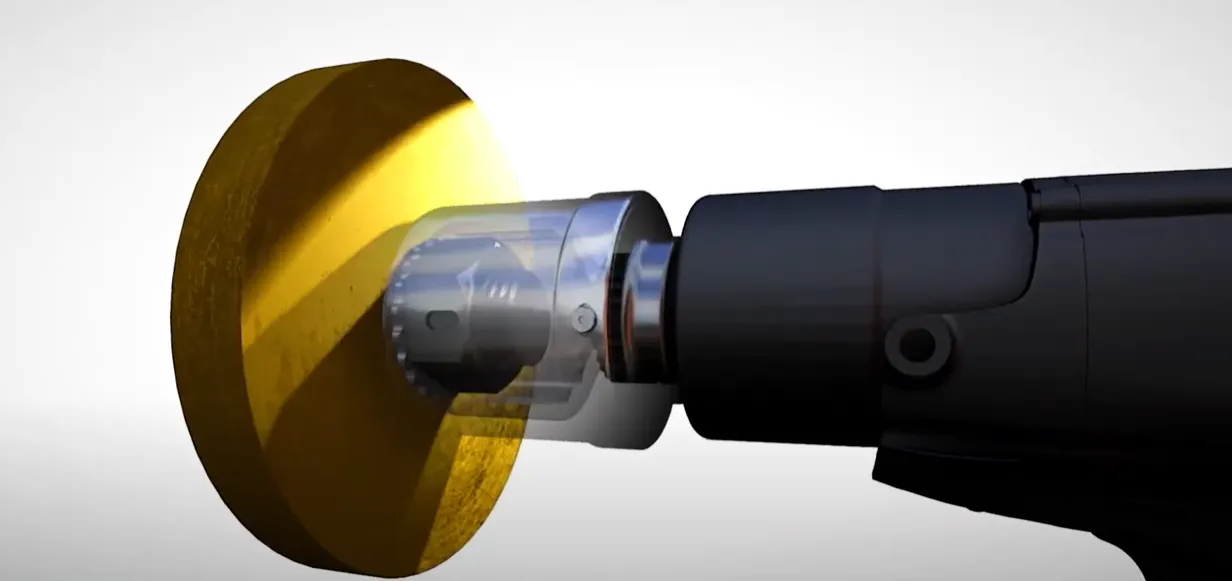

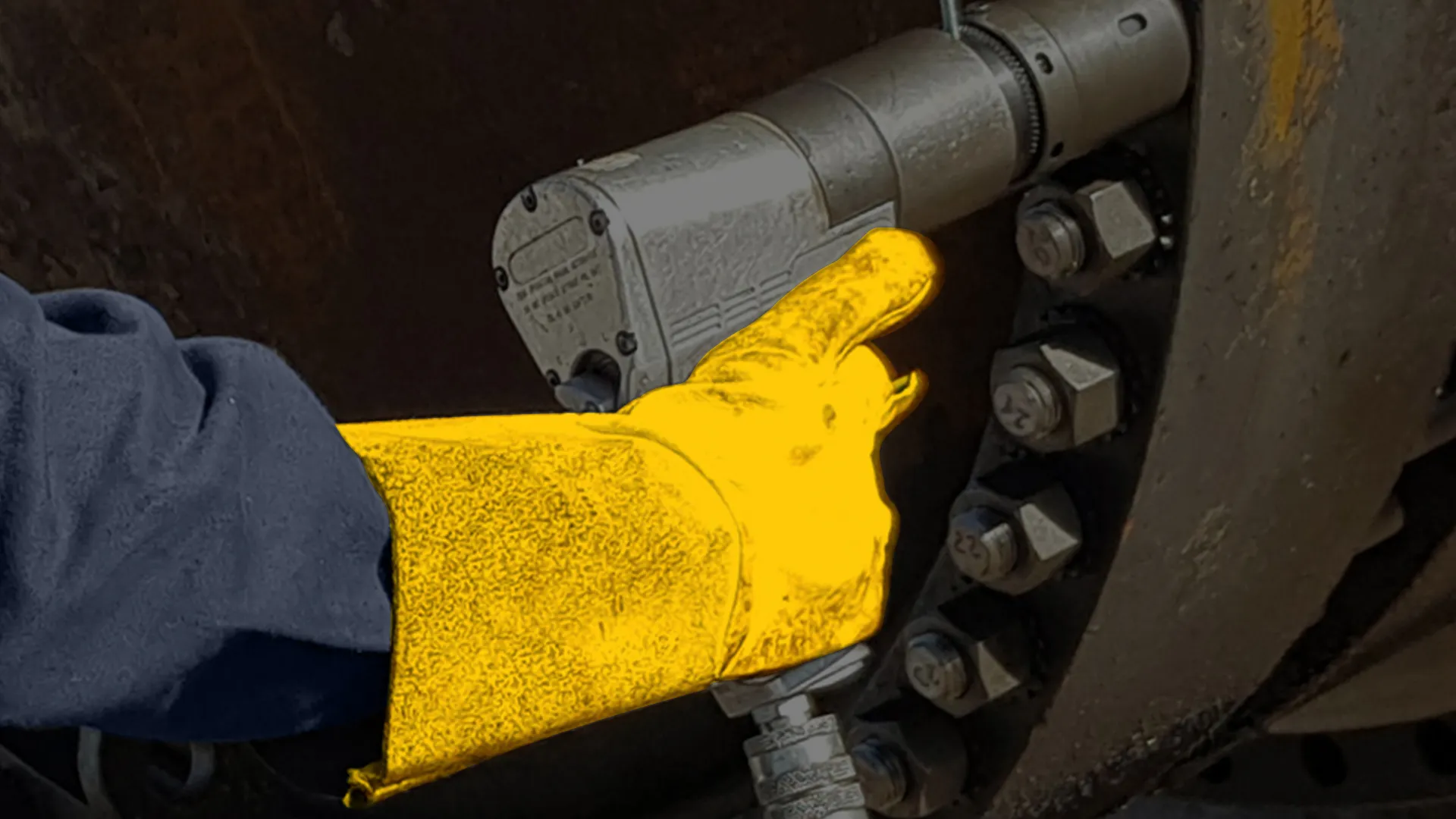

That’s the problem the HYTORC Washer solves with elegance. No special fixtures, no extra hands, and no reaction arm. Just one tool, one socket, and a smooth, intuitive process. It’s so easy to use that it reduces the risk of operator error and requires minimal training—critical benefits in harsh or isolated environments.

Its practical benefits extend beyond safety and ease. The HYTORC Washer protects flange surfaces, reduces stress on tooling, and supports reusability of nuts and bolts. With fewer damaged components and less downtime, you’re looking at lower long-term costs and better operational uptime.

So, let’s make it official: Throw your reaction arms in the trash. A safer, smarter system is here.